Project Blue Vanadium Market Report

Vanadium is a key transition metal used in greener steel and energy storage applications.

Global decarbonization efforts are expected to drive new demand in the vanadium sector.

- Vanadium contributes to reducing 0.38% of global fossil carbon footprint from its use in micro alloyed steel

- Demand for low-carbon technology should require 173% more vanadium production by 2050

- Burgeoning stationary energy storage demand to driven by the integration low-cost renewables and new net-zero policy

Growth in VRFBs and additional new economy use cases may put upward pressure on prices without new primary or secondary supply.

Energy Storage

- Vanadium batteries are ideally suited for grid storage solutions

- Long duration energy storage expected to reach 80-140 TWh by 2040

- ~10,000 mt of V2O5 is required for each GWh of VRFB energy storage

Low Carbon Steel

- Global push for the utilization of lower carbon steel;

- Achievable weight reduction of at least 25%. 3 tons of vanadium micro-alloyed steel may replace 4 tons of carbon manganese steel.

Developing Countries

- Developing countries expected to drive consumption through greener steel production and changes in the regulatory environment.

- Infrastructure spending programs expected to boost steel and vanadium consumption.

Vanadium + Li-ion

- Vanadium-based cathode coating expected to enable cobalt reduction for a more advanced technology use.

- Vanadium-based anode in lithium-ion battery technology expected to extend Li-ion battery life and provide ultrafast charging.

Smart Glass

- Vanadium dioxide “smart glass” coatings stop the escape of thermal radiation and prevent heat loss.

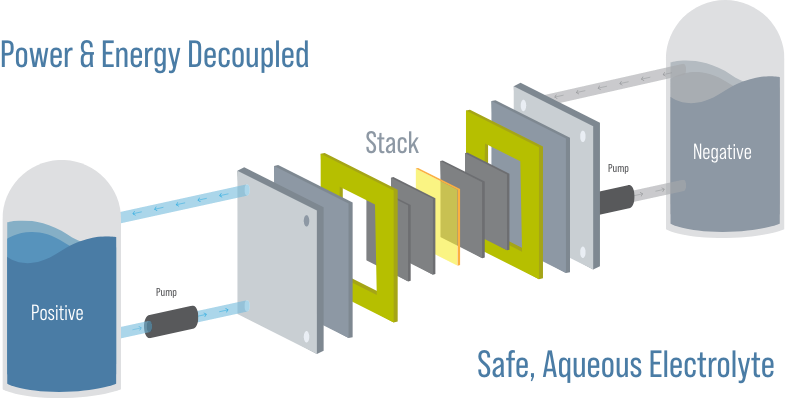

Vanadium batteries: ideally suited to power the world’s long duration energy storage needs

Water-based electrolyte

Eliminates the risk of fire or release of harmful gases into the environment.

Exists in 4 different oxidation states

Removes the potential for cross-contamination which is inherent in other flow batteries.

Cost-effective

Recycling and reusing the vanadium electrolyte in a new VFRB potentially reduces the battery’s energy costs.

Reduces carbon footprint of vFrbs

Recycling the vanadium electrolyte can reduce carbon emissions by up to 78% per MWh.

No loss of efficiency at end of life

Vanadium in the electrolyte retains its efficiency regardless of number of charge/discharge cycles.

Vanadium supports the ESG investment case with non-degrading, fully recyclable electrolyte used in vanadium batteries.

Vanadium batteries: designed to last for decades

- Flow battery uses vanadium electrolyte in cathode and anode eliminating cross contamination.

- PositiveSafe, Aqueous ElectrolytePower & Energy DecoupledStackPumpNegativePump last for decades, are reusable, and non-degrading electrolyte allows for unlimited use.

Resources on Vanadium, VRFBs and Long Duration Energy Storage

Assessing the role of vanadium technologies in decarbonizing hard-to-abate sectors and enabling the energy transition

Summary

The decarbonization of heavy industry and the emergence of renewable energy technologies are inextricably linked to access to mineral resources. As such, there is an urgent need to develop benchmarked assessments of the role of critical elements in reducing greenhouse gas emissions. Here, we explore the role of vanadium in decarbonizing construction by serving as a microalloying element and enabling the energy transition as the primary component of flow batteries used for grid-level storage. We estimate that vanadium has enabled an avoided environmental burden totaling 185 million metric tons of CO2 on an annual basis. A granular analysis estimates savings for China and the European Union at 1.15% and 0.18% of their respective emissions, respectively. Our results highlight the role of critical metals in developing low-carbon infrastructure while underscoring the need for holistic assessments to inform policy interventions that mitigate supply chain risks.

Net-zero power: Long-duration energy storage for a renewable grid

Summary

As the world transitions to decarbonized energy systems, emerging long-duration energy storage technologies will be critical for supporting the widescale deployment of renewable energy sources.Structure-properties relationship of ultra-fine grained V-microalloyed dual phase steels

Summary

The effect of vanadium microalloying on ultra-high strength dual phase (DP) ferrite-martensite steel microstructure and properties was studied. It was found that the addition of 0.14 wt% V to a Fe-0.18C-1.5Mn-0.3Si-0.008N reference alloy introduced very significant ferrite grain size refinement in the cold rolled and annealed state. During continuous annealing the initial ferrite to austenite transformation kinetics were strongly retarded, however under slow cooling both pearlite and bainite transformations were suppressed indicating increased hardenability. After cold rolling and intercritical annealing at 750 ⁰C intense V(C,N) precipitates (mean radius 3.7 nm) were observed in the ferrite phase whereas precipitates were scarce in martensite (austenite) and much larger (mean radius 6.7 nm). Significant gains in YS, UTS and work hardening rate were observed at low martensite fractions due to a combination of selective precipitation strengthening and grain refinement of ferrite. However, at higher martensite fractions (> 45%) the YS, UTS and work hardening rate became lower than the reference, primarily due to softening of the martensite. The latter was attributed to the fixing of solute carbon by V(C,N). The net increase in tensile strength with martensite content of the vanadium alloy was ~ 4 MPa/%α’ compared to ~ 16 MPa/%α’ for the reference alloy. A recently developed size-sensitive mean field structure-properties model was extended to capture these microalloying effects. At iso-tensile strength both the fracture strain and hole expansion behaviour of the new microalloyed steel showed improved performance over the reference.